The research field

The scientific objective of the IMPACT department is to gain a better understanding of the relationships between processes, microstructures and material properties.

A major part of the research carried out here is focused on lightweighting structures and hydrogen storage to support the energy transition. The global aim is to improve the understanding of the phenomena involved in the generation of textures and microstructures during the shaping (thermomechanical and physicochemical treatments, severe deformation, additive manufacturing) or loading (deformation, fatigue, hydrogen embrittlement) of multiphase polycrystalline materials.

The influence of microstructures on behavior (yield strength, work hardening, ductility, fatigue resistance) is also studied to optimize the mechanical and physical properties of materials.

Orientation microscopy

Interfaces

Composites

Microstructures

Anisotropy

Fatigue

Micromechanics

Crystal plasticity

Hydrogen

The members

Professors and research directors

No content was found.

Lecturers and research associates

No content was found.

Technical staff

No content was found.

PhD students

No content was found.

Post-doctoral fellows and contract researchers

No content was found.

Guests – other staff

No content was found.

Research areas

Genesis and properties of microstructures and textures – Development of innovative techniques

Coordinators: Nabila Maloufi and Lionel Germain

The aim of this area is to develop innovative techniques for characterizing materials. These techniques are applied, among other things, to understanding the genesis of multiphase, often nanometric microstructures with heterogeneous spatial distributions of micro-constituents, in order to understand and optimize their properties in relation to their elaboration process.

Recent innovations include:

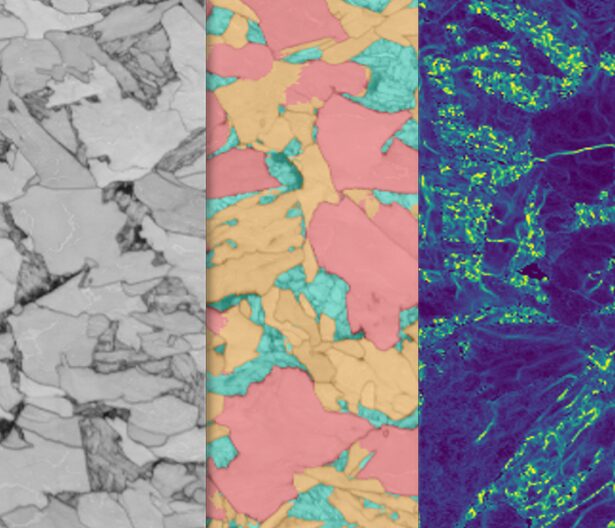

EBSD WITH VERY HIGH ANGULAR RESOLUTION

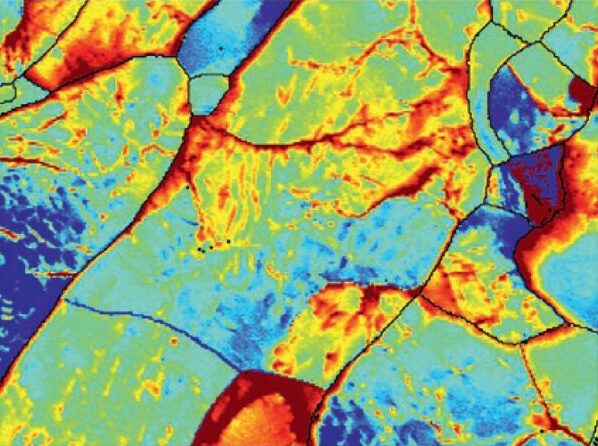

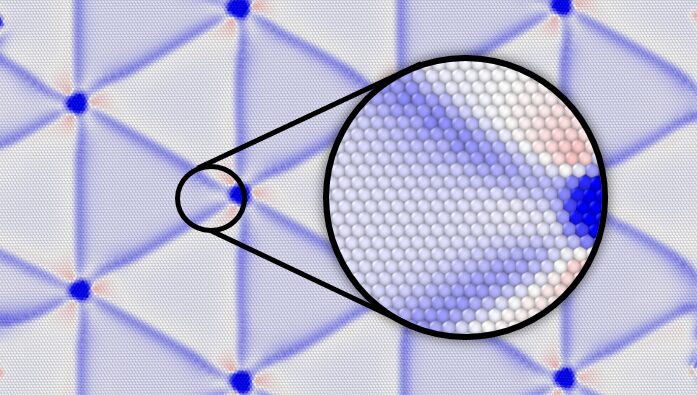

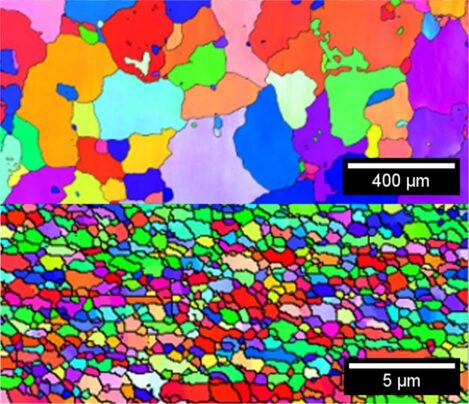

A new digital image correlation technique is applied to EBSD to map disorientations with high angular resolution, as well as geometrically necessary dislocation densities and elastic deformations. This new method is implemented in the ATEX software.

EBSD MAP PROCESSING USING ARTIFICIAL INTELLIGENCE

A U-Net model was trained to perform bainite, ferrite and martensite segmentation on EBSD maps. The model surpassed human performance: it could differentiate the three phases with an average accuracy of 92%.

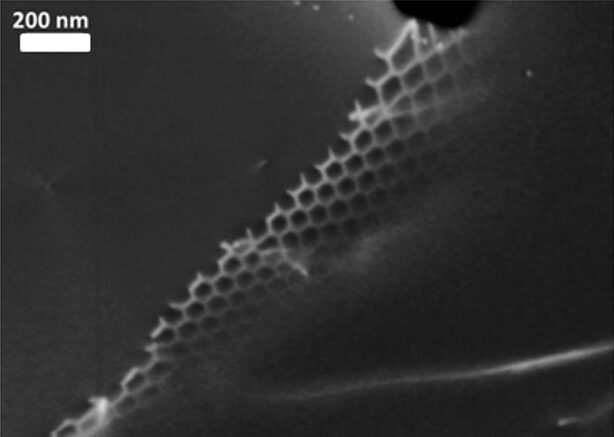

TKD ON-AXIS

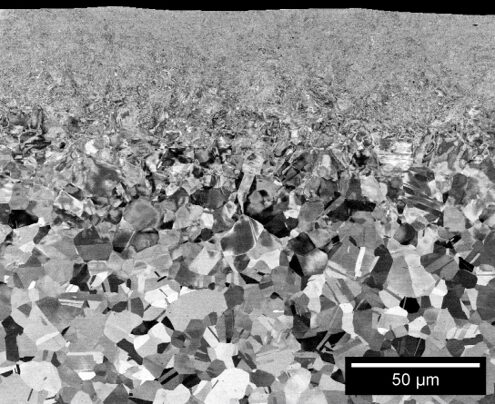

A new configuration for transmission Kikuchi diffraction (TKD) in the SEM has recently been developed, with a scintillator perpendicular to the electron beam. This configuration, called “on-axis” TKD, makes twin and grains smaller than 10 nm clearly visible with a high indexing rate, as demonstrated with electrodeposited nanocrystalline Ni.

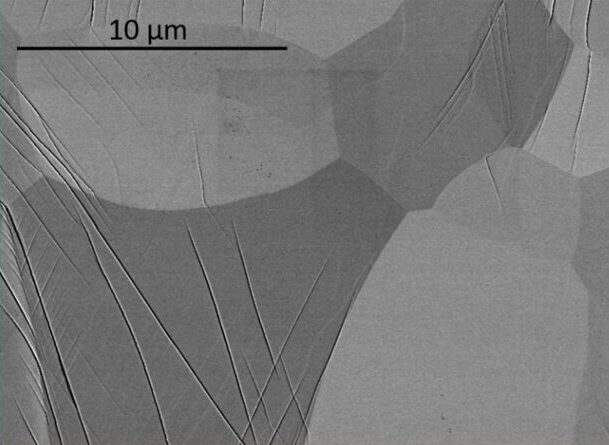

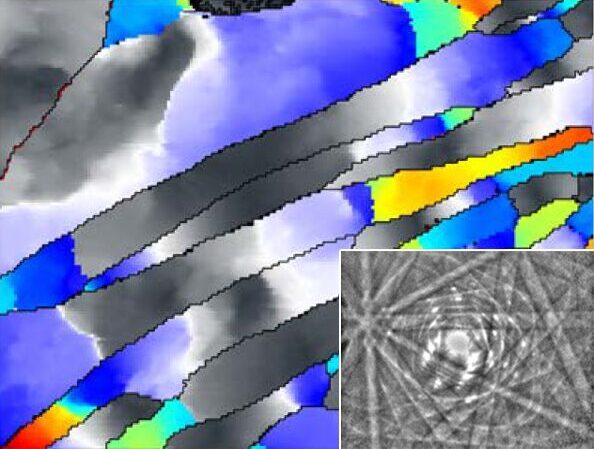

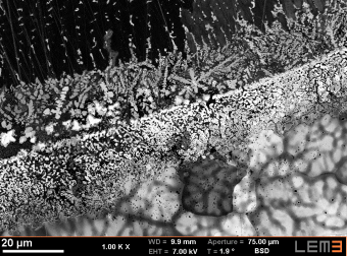

HR-SACP AND ACCURATE ECCI

The development of an electron beam precession mode in a Zeiss scanning electron microscope for the production of sub-micron lateral resolution “HR-SACP” channeling diagrams, has paved the way for the fine characterization of crystalline defects in bulk materials by “A-ECCI” Electron Channeling Contrast Imaging, thanks to an innovative procedure. For the first time, for example, a variety of creep deformation substructures were revealed in a UO2 ceramic.

OBTAIN QUASI-MONOCRYSTALS OF COPPER BY RECRYSTALLIZATION BETWEEN GRAPHENE SHEETS

Our researchers have shown that by sintering copper foils laminated between graphene nanosheets, it is possible to direct the recrystallization of copper and form a quasi-single crystal with a cube orientation. The anisotropic expansion of graphene imposes elastic stresses which are at the origin of this phenomenon.

Micro- and nano- mechanics, self-organization, plasticity and interfaces

Coordinators: Vincent Taupin, Julien Guénolé and Antoine Guitton

Researchers in this research team study the influence of nano-structure / micro-structure on the physical and mechanical properties of materials, using innovative experimental, theoretical and numerical methods. More specifically, the team is interested in the relationships between the collective organization of defects and microstructure in plasticity (dislocations, solute atoms), the associated characteristic internal lengths, the presence of crystalline interfaces (grain, phase or twin boundaries) and the local and macroscopic physical properties of materials (metallic alloys, ceramics, semiconductors, intermetallics). The experimental characterizations, the theories and models developed concern all the size scales involved, from the atom to the macroscopic scale. The team also relies increasingly on optimization and analysis methods from the field of machine learning (artificial intelligence).

Étude des défauts linéaires dans les cristaux via la transformée de Fourier rapide

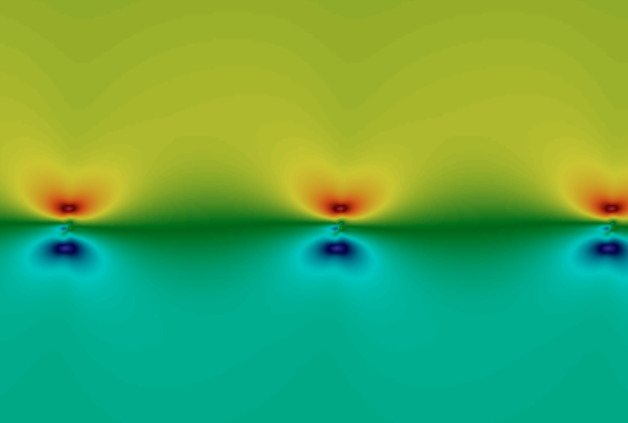

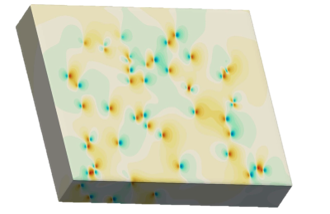

Recent interest in spectral methods using the Fast Fourier Transform (FFT) in mechanics has led to a focus on local mechanical fields and interfacial defects. We propose here a new numerical approach to deal with material discontinuities, such as disclination dipole distributions interacting with inhomogeneities and grain boundaries.

ADJUSTMENT OF TITANIUM MECHANICAL PROPERTIES: ADVANCED CHARACTERIZATION AND AUTOMATIC DATA ANALYSIS

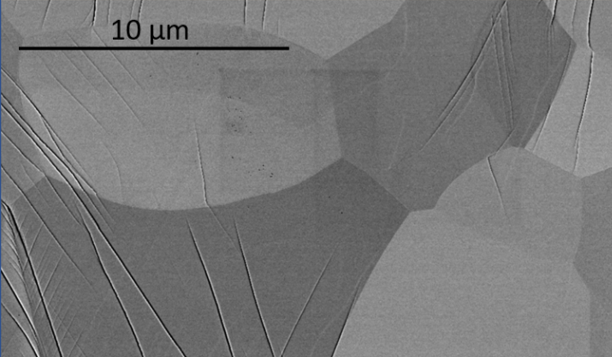

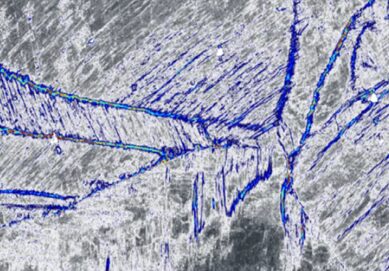

A new automated method of slip trace detection using the Hough transform is introduced for electron channeling contrast imaging (ECCI). Enhanced with orientation data, it facilitates rapid indexing of slip tracks and reliable statistical studies.

COUPLING ELECTRON TOMOGRAPHY AND DISLOCATION MODELING

Dislocation networks of an olivine single crystal characterized by 3D tomography in the transmission electron microscope are used as input to a dislocation field mechanics model. Observed dislocations are taken into account through a geometrically necessary equivalent dislocation density. The model provides the output mechanical fields, thus completing the experimental characterization.

MESOSCOPIC COMPLEXITY IN THE PLASTIC FLOW OF A HIGH-ENTROPY ALLOY

Plastic flow in solids is challenged by the self-organization of crystalline defects, especially in High Entropy Alloys (HEA). This study explores the mesoscopic complexity of plastic flow in an Al0.3CoCrFeNi alloy. Various methods reveal transitions between similar dynamic regimes at different noises, including the rare blue noise, and reddened behaviors.

CHARACTERISTICS OF A FLEXURAL JOINT IN PHASE MAX TI3ALC2

MAX phases, complex materials, combine the properties of metals and ceramics thanks to their layered structure. Detailed microscopy reveals a nano-twist phase in Ti3AlC2. The role of disclinations in representing the stress field is explored, with implications for materials design.

Development and optimization of microstructures related to the processes

Coordinators: Laurent Weiss and Jérôme Serri

This area is dedicated to improving material properties by controlling manufacturing processes. It is based on techniques ranging from powder elaboration (mills and attritors) to specific consolidation methods (hyper-deformation, SLM machine).

Studies also cover hyper-deformation of solid materials and mechanical surface treatments (SMAT) to induce structural modifications for material reinforcement. The team draws on the skills developed by laboratory researchers in both fine physico-chemical characterization (EBSD, 3D FIB analysis) and thermo-mechanical characterization (tribo-contact analysis, nano-indentation) for the analysis of modified volumes, surfaces and sub-surfaces.

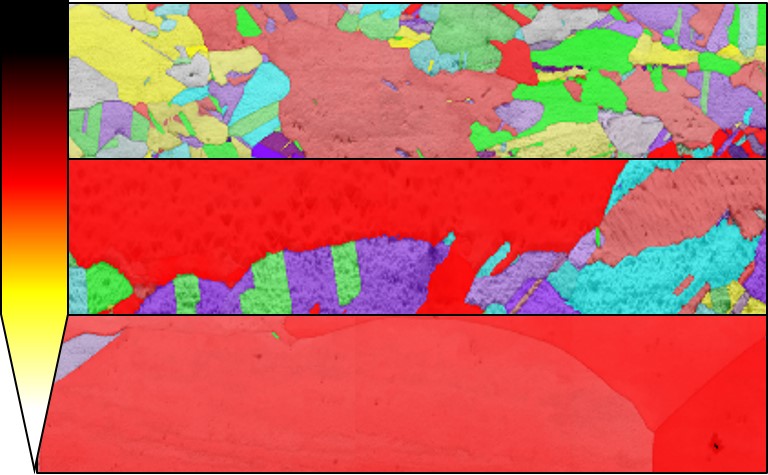

MODIFICATION OF SURFACE PROPERTIES BY MECHANICAL SURFACE TREATMENT

The surface of materials is a special zone responsible for mechanical strength and interaction with the surrounding atmosphere. By modifying its properties through mechanical surface treatment (e.g. ultrasonic shot peening), it is possible to improve the fatigue life of service parts, modify surface reactivity or enhance the biocompatibility of treated parts.

REFINEMENT OF MICROSTRUCTURES BY SEVERE PLASTIC DEFORMATION

One way to improve mechanical strength is to reduce grain size. This can be achieved by subjecting solid materials or powdered primers to severe plastic deformation, to considerably refine grain size down to the submicrometer scale.

OPTIMIZATION OF ADDITIVE MANUFACTURING MICROSTRUCTURES

In additive manufacturing, modifying the “deposition parameters/materials” pair enables a wide range of properties to be obtained, resulting from a combination of the macroscopic structure (lattice, bulk, etc.), the intrinsic physico-chemical properties of the materials and the microstructure. Scientific mastery of these relationships leads to technological leaps for industry.

Thermomechanics, damage and durability of materials, composites and structures

Coordinators: Julien Capelle and Marwa Abida

This research area focuses on understanding the thermo-mechanical behavior and relationships between processes, microstructures, properties and durability of materials and structures. In particular, the studies undertaken aim to gain a better understanding of the thermo-mechanical behavior of large-scale components and structures, while taking into account the evolution of microstructural characteristics under load, with a view to optimizing their performance.

The research area also seeks to study the influence of the presence of defects, microstructural heterogeneities, residual stresses and/or damage under mechanical loading in corrosive atmospheres (hydrogen, ammonia).

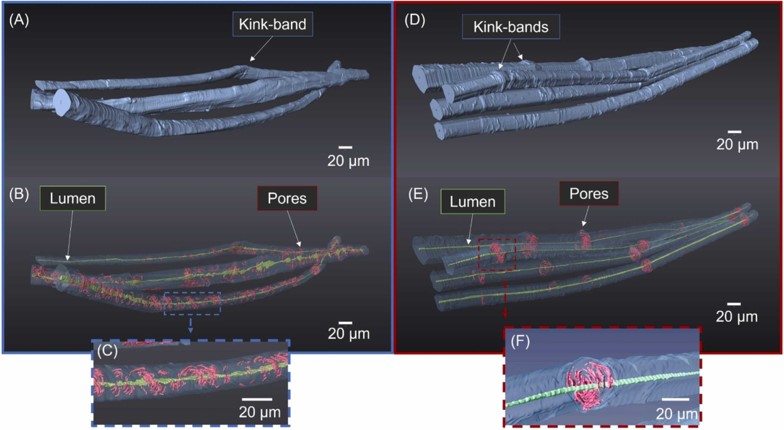

3D RECONSTRUCTION FROM TOMOGRAPHIC FIBER ACQUISITIONS

Individual flax fibers exhibit morphological deformations, known as kink-bands, which are considered to be areas of weakness. The correlation between the occurrence of kink-bands, the method of fiber extraction and the mechanical properties of the fibers was investigated. An in-depth multi-scale statistical study was carried out on 96 elementary fibers extracted from four different batches processed under different plant fiber extraction conditions (scutching and combing).

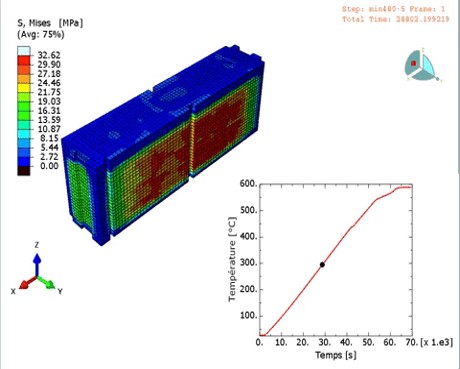

THERMOMECHANICAL NUMERICAL SIMULATION REPRODUCING THE BRAZING CYCLE OF A WAVE-PLATE-BAR ASSEMBLY USING FE

Al3003 is a widely used general-purpose aluminum alloy. Assemblies involving these alloys are often subjected to thermomechanical loading at variable strain rates. Finite element (FE) simulation of the performance of these assemblies requires the material behavior to be obtained using an appropriate constitutive model. Here, an elasto-viscoplastic model has been proposed.

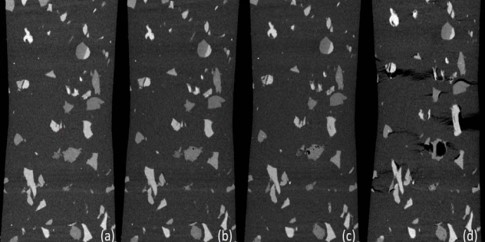

FORMULATION AND EXPERIMENTAL CHARACTERIZATION OF COMPOSITES BASED ON POLYPROPYLENE AND WASTE TIRE RUBBER (WTR)

In-situ tensile tests using X-ray tomography were used to monitor damage to the polypropylene composite loaded with waste tire rubber. The results were correlated with tensile tests on conventional machines and modeled using FEM methods.

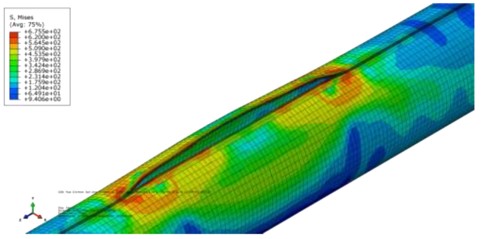

Probabilistic Design Factors for Pipes Used for Hydrogen Transport

The method used involves a risk equation defined as the product of the probability of leakage after failure, the probability of gas flow exceeding a prescribed value, the probability of ignition, the probability of lethal effects exceeding a threshold value, and the probability of the presence of a person, corrected by an environmental factor and a risk reduction coefficient. The results obtained are less conservative than the deterministic values provided by the ASME code.

Thesis in progress

Thesis in the IMPACT department

No content was found.