The MécaRhéo (Mechanics and Rheology) platform is organized around experimental resources enabling the static, vibratory, and dynamic mechanical characterization of materials and structures for applications in the fields of aeronautics and transportation, soil and granular materials, biomechanics, and printed circuits.

SHARED RESOURCES

The technical facilities enable us to address the scientific and technological challenges faced by the laboratory by determining the mechanical properties, service life, and resistance of materials and structures, among other things. Specific metrology is developed to ensure that experiments meet the needs of research and our industrial partners.

For more information about the experimental resources, please contact the facility and/or platform managers.

Technical Facilities

Experimental Biomechanics Area (EBE)

Contacts: Adrien Baldit and Émilie de Brosses

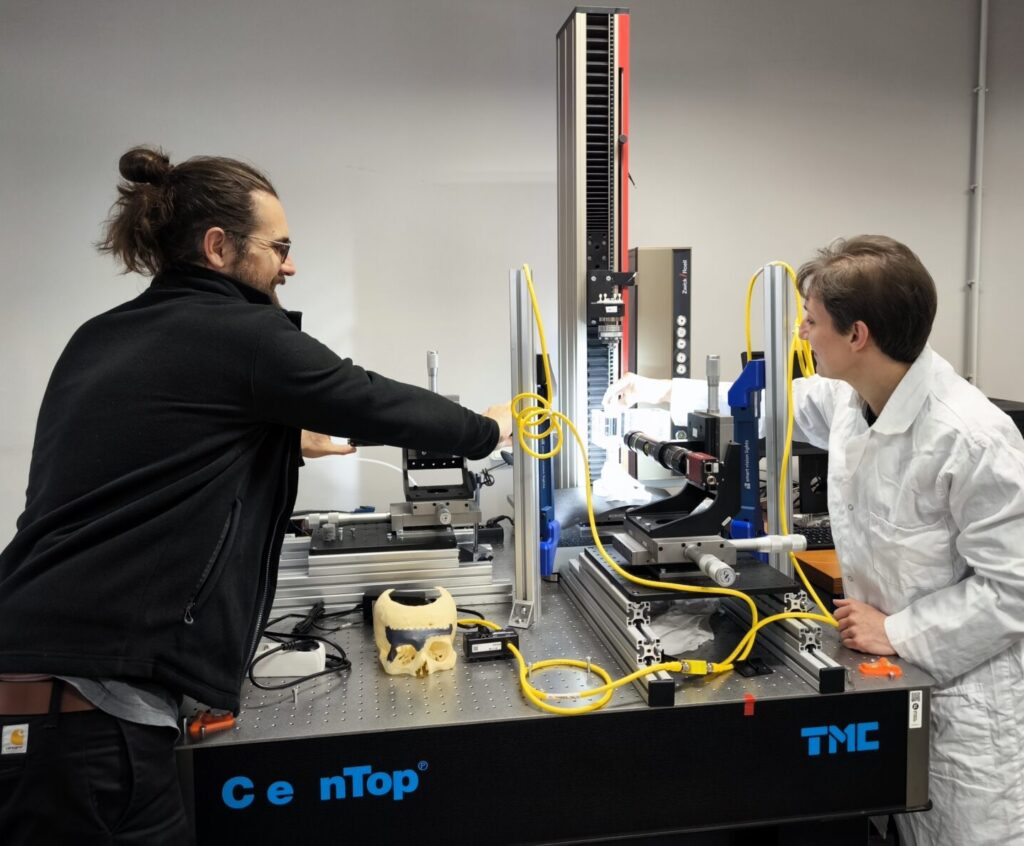

Technical facility dedicated to characterizing the behavior of living tissues and their substitutes. The EBE consists of an L2-type laboratory dedicated to the storage and preparation of biological samples of animal origin, as well as an experimentation room equipped with conventional testing machines that enable characterization at various scales and ranges of stress, under quasi-static or dynamic conditions (very low load machine <1N, Zwicky 0.5 with 10N, 100N, and 500N load cells, Instron E10000 with 1kN and 10kN load cells).

Ad hoc assemblies are designed to reproduce stresses close to the physiology of the materials (or tissues) and structures (or organs) being tested, in an environment with controlled temperature and humidity.

Rheology and dynamic rupture

Contact: Richard Bernier

Designed to characterize the dynamic behavior of materials under compression and shear using gas cannons reaching speeds of over 50,000 s-1, and to conduct ballistic studies to understand the processes involved in the failure of materials during perforation. These test benches are equipped with systems that allow testing at temperatures ranging from -180°C to +300°C.

- Split Hopkinson Pressure Bar (SHPB) bench

- 6mm and 13mm caliber ballistic bench

Laboratory for the Study and Modeling of Printed Circuits (LEMCI)

Contact: Gautier Girard

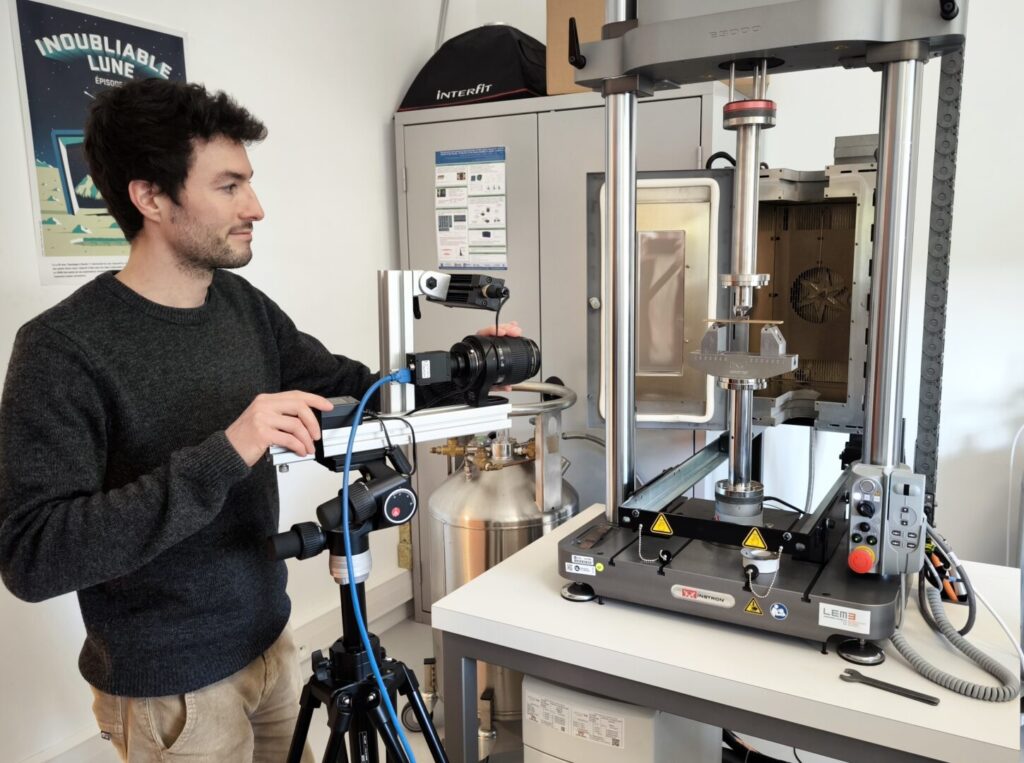

Primarily devoted to the study of materials, interfaces, and structures of printed circuits under intense thermal loads. Test machines, accessories, and sensors are used to identify the thermomechanical behavior of thin materials (copper films, composites), their thermal expansion behavior, the interface energies between different materials, etc. The reliability of printed circuit boards can be tested by imposing thermal cycles in a controlled environment chamber.

The main equipment used in this experimental facility is as follows:

- Instron E3000 electrodynamic tensile testing machine, equipped with a thermal chamber and tensile, compression, and 3- and 4-point bending fixtures. Deformation measurements are performed using digital image correlation.

- Netzsch TMA 402 F1 Hyperion thermomechanical analysis machine for expansion measurements between -150 and 1000°C, including tension, expansion, penetration, and 3-point bending fixtures.

- MTS tensile testing machine equipped with a peel test bench.

- Climats Extrême 320 T climatic chamber for performing environmental tests with controlled temperature and humidity.

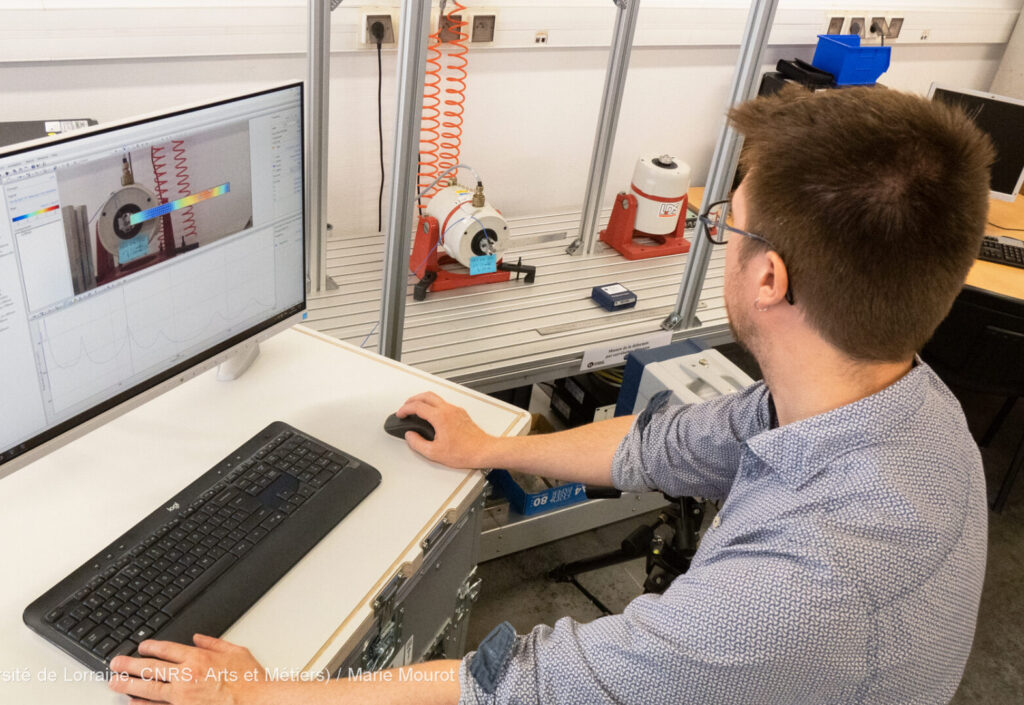

Vibration and wave propagation (VIB)

Contact: Guillaume Robin

Provides vibration characterization and analysis of structures to improve damping. The platform consists of a set of vibrators ranging from approximately 10 g to 100 g.

The vibrator with a capacity of 100 g when empty has a frequency range of 4 to 4000 Hz. A thermal chamber fits over the vibrator to place the test piece under climatic conditions. Vibration measurement is performed either by accelerometers in contact with the structure or by single-point or scanning laser vibrometry (non-contact measurement of full-field vibrations).

This experimental investigation is combined with inverse identification methods to determine mechanical properties.

The facility also includes means of measuring ultrasonic wave velocities to characterize mechanical properties.

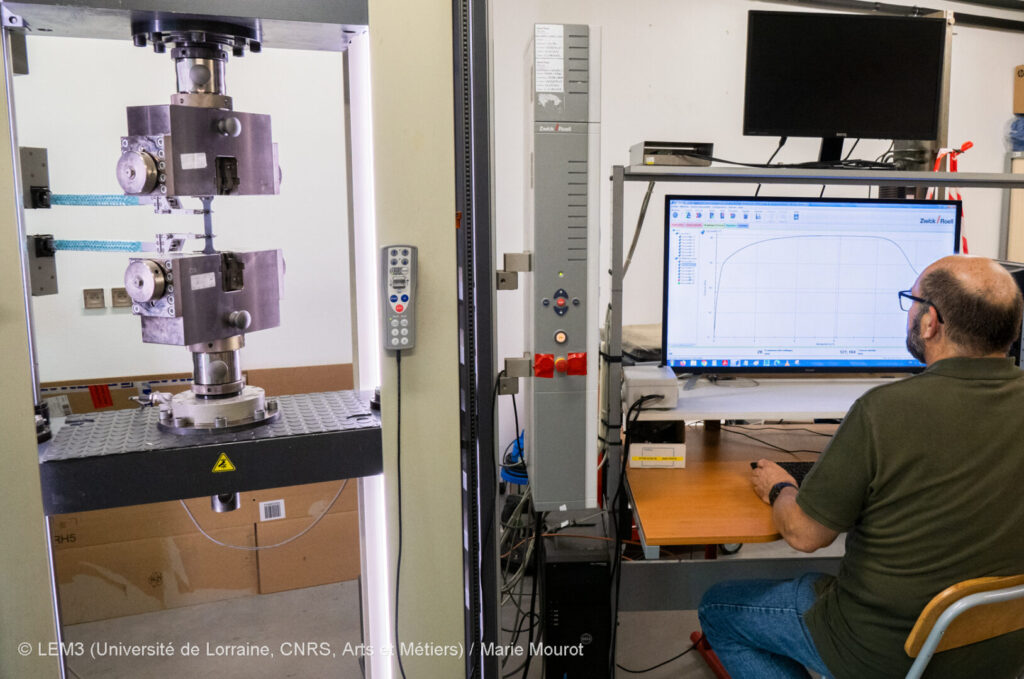

Mechanical characterization of materials (Meca)

Contact: Patrick Moll

Dedicated to the mechanical characterization of materials under quasi-static or dynamic stress.

Our setups enable compression, tension, or 3-point bending of the test specimens under study, as well as controlled temperature testing. Contact and non-contact metrology provided by the extensometer measures elongation, enabling the determination of stress as a function of deformation.

- Universal testing machine (tension, compression, bending, etc.) with a maximum capacity of 100kN.

Available load cells: 100kN, 10kN, and 1kN.

Motorized long-stroke contact extensometer (700mm-L0). - ZWICK Z250 universal testing machine (tension, compression, bending, etc.) with a maximum capacity of 250kN.

Available equipment: 250kN load cell, non-contact laser and video extensometry. Testing in thermal chamber (-70, +250°C). - ZWICK Z1200 universal testing machine with a maximum capacity of 1200 kN (tension, compression).

Available equipment: 1200 kN load cell, compression plate, grooved table for mounting adaptations, 1100° tubular furnace.

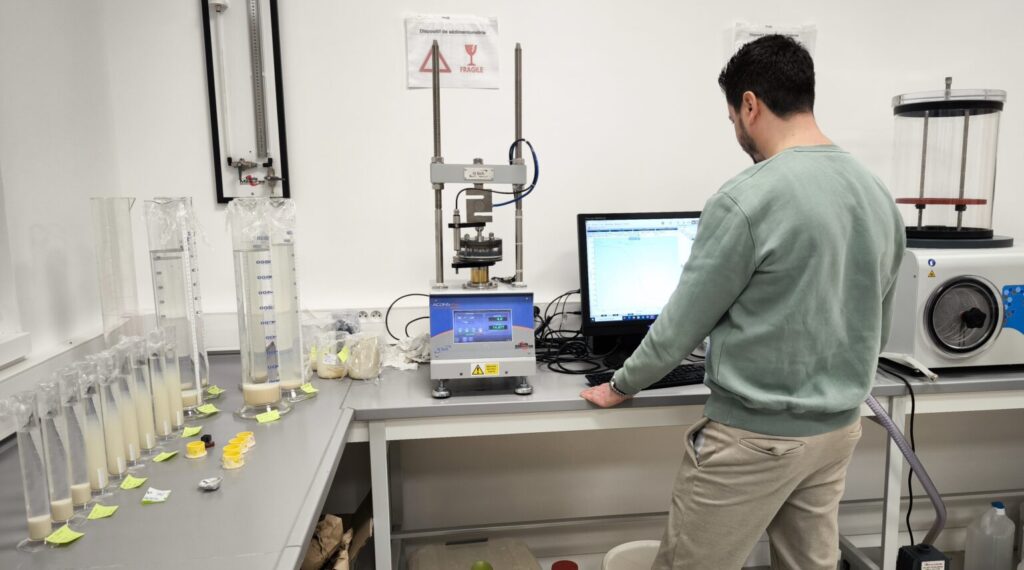

Hydro-mechanical behavior of geomaterials (Geo-Mat)

Contacts: Fares Bennai and Mohamad Jrad

Enables the study of civil engineering materials, in particular the consolidation and three-dimensional conditioning of clay materials for analysis.

The behavior of soil materials is also investigated under hydric and thermal conditions.

Selected Publications

Anais Lavrand, Lorinne Adam, Alexis Da Rocha, Flora Lemaire, Capucine Loth, Adrien Baldit, et al.

2025, International Journal of Biological Macromolecules

Guillaume Robin, Thomas Huchard, Marc Ponçot, El Mostafa Daya

2025, Mechanics Research Communications

Fares Bennai, Mahdia Hattab, Yanzheng Ding, Mohamad Jrad, Julien Guyon

2025, OP Conference Series: Earth and Environmental Science

Amine Bendarma, Alexis Rusinek, Christophe Czarnota, Tomasz Jankowiak, Richard Bernier, Tomasz Lodygowski

2025, Composite Structures

Paul Perin, Gautier Girard, Marion Martiny, Sébastien Mercier

2024, Microelectronics Reliability